EC Flow Cells

Using flow devices to advance electrochemistry

Motivation

Electrochemical flow cells allow precise control over mass transport and fluid dynamics, facilitating initial scale-up assessments for industrial and commercial applications. This configuration enables a realistic evaluation of electrode materials, kinetics, and long-term stability across diverse fields, including electroanalysis, environmental remediation, wastewater treatment, electrosynthesis, and various electrochemical energy systems such as microbial fuel cells, electrolyzers, and flow batteries. Despite their advantages, the high costs associated with materials and machining of critical components limit the use of commercial filter-press flow cells in research. Alternatively, 3D-printed flow devices offer a cost-effective solution for testing various electrochemical systems at the laboratory scale and for rapid industrial prototyping.

I aim to develop new device configurations to advance the evaluation of electrochemical processes across a broad spectrum of applications, from environmental remediation to energy systems. I am particularly focused on exploring more efficient configurations and advancing manufacturing techniques like 3D printing to facilitate quick prototyping and integration into research.

Research Projects

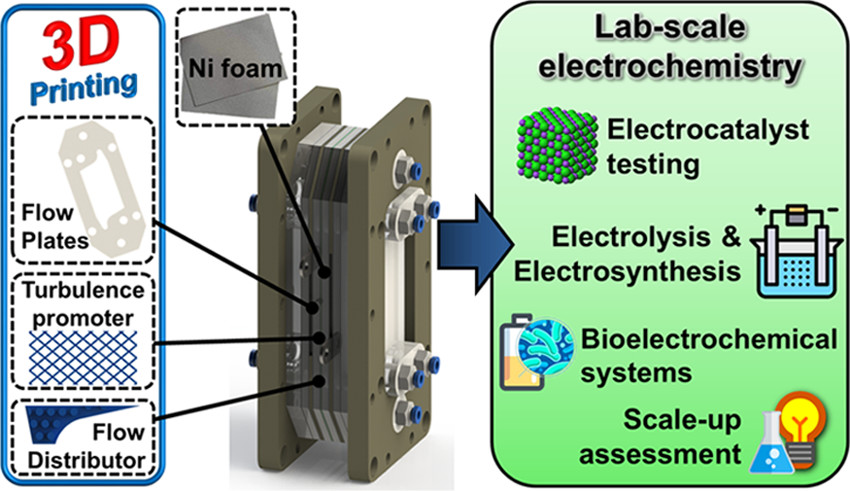

In this study, we utilized 3D printing to design and optimize an electrochemical flow cell suitable for lab-scale testing of diverse electrochemical processes (Figure 1). This approach combines CAD/3D printing with the traditional characterization of filter-press reactors. We also examined the chemical stability of 3D-printed materials to verify the viability of 3D printing.

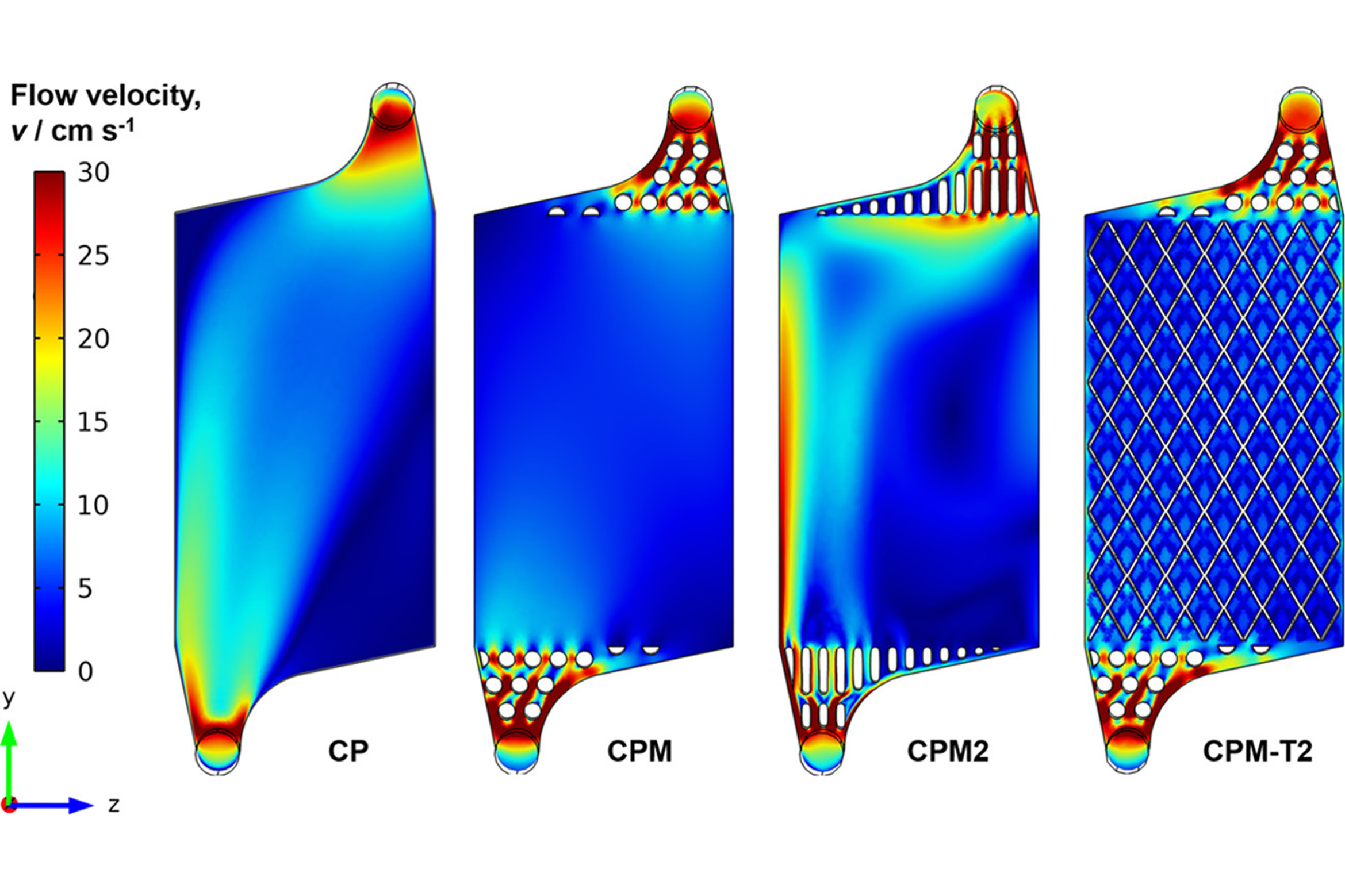

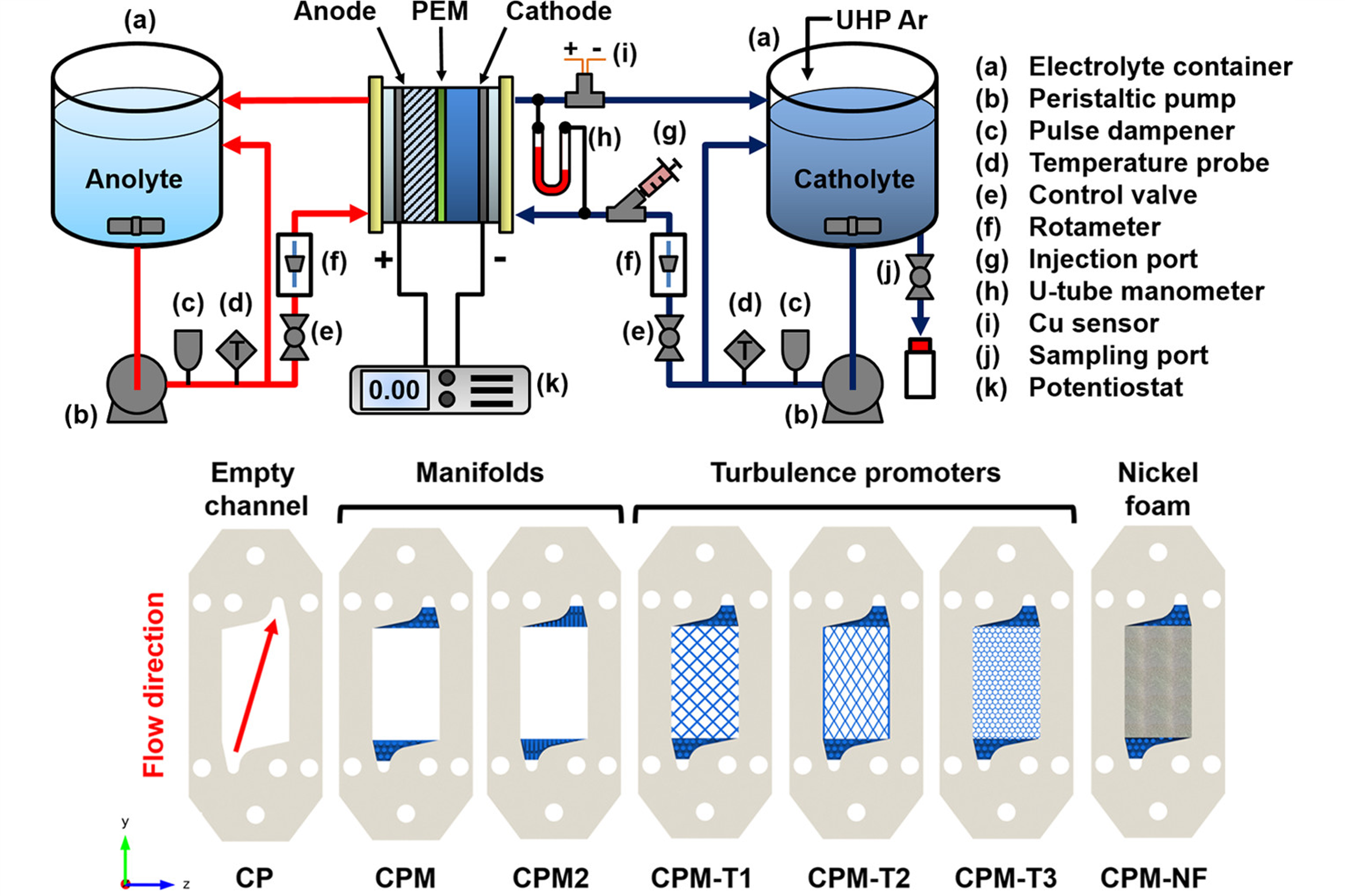

We examined various cell configurations, incorporating turbulence promoters and flow dissipators to improve the hydrodynamics and mass transport in the filter-press electrochemical reactor (Figure 2).

Furthermore, we conducted comprehensive studies on the hydrodynamics, flow distribution, and mass transfer characteristics of these electrochemical flow cells using COMSOL Multiphysics simulations, tracer injection tests, and dimensional analysis (Figure 3).