Process Design and Simulation

Optimizing sustainable processes for fertilizer production

Motivation

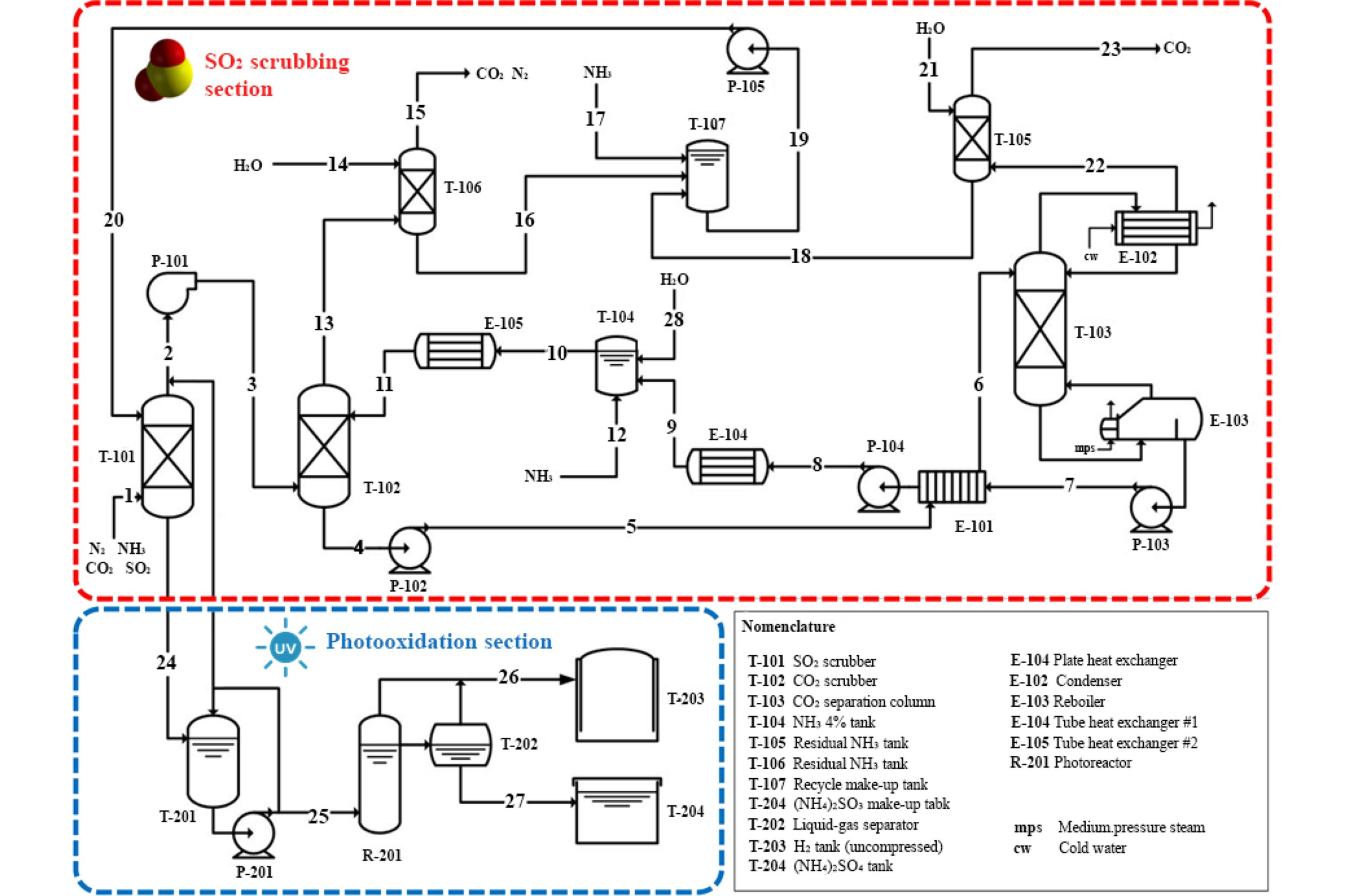

Coal-fired power plants use flue gas desulfurization (FGD) technologies, such as ammonia-based wet FGD, to capture sulfur dioxide and prevent its release into the atmosphere. This process converts aqueous ammonium sulfite into ammonium sulfate via oxidation with ozone, subsequently dried and sold as fertilizer. While commercially viable, this process can be made more sustainable by replacing ozone oxidation with energy-efficient photochemical and electrochemical methods, facilitating hydrogen release and enhancing economic viability. Although the photochemical approach is promising due to the abundance of solar resources, further understanding of the kinetics of aqueous ammonium sulfite photooxidation and its integration into industrial FGD systems is needed.

My goal is to implement more sustainable operations in industrial processes, especially through photo and electrochemical technologies, to improve energy efficiency and incorporate renewable energies. I am also interested in developing catalytic conversion and separation techniques alongside more efficient reactor configurations to enhance the energy-water nexus and reduce environmental impact.

Research Projects

In this project, our team developed a flue gas desulfurization plant incorporating a photochemical step to convert SO2 into hydrogen and ammonium-based fertilizers. I led the process simulation and optimization of the plant, utilizing the kinetics of the photochemical reaction to model the reactor (Figure 1).